Tips & Tricks

Cracks on rear axle suspension

The older models had a single axle-body as the rear axle, which was sprung by means of a parallel rocker. Cracks have often appeared on this swing arm, which have even led to the complete loss of the axle.

The images below show where these cracks occur.

The precautionary use of reinforcement plates seems advisable.

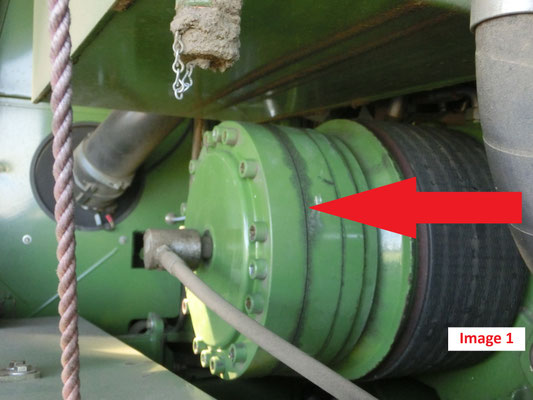

Coupling for main drive

The main drive clutch on all forage harvesters is exposed to significant heat stress due to the unavoidable minimal slippage of the power belts. On Krone forage harvesters, as with most other manufacturers, the main drive clutch is hydraulically actuated via the low-pressure hydraulic system.

Ultimately, this clutch is nothing more than a simple hydraulic cylinder that presses several friction pads together.

This creates the frictional connection.

Inside this "hydraulic cylinder" is a turquoise sealing ring, the plastic of which cannot withstand this enormous heat stress over time.

The plastic slowly hardens, and a very slight oil leak occurs. This oil then slowly seeps onto the friction pads, which subsequently can no longer transmit the torque generated by the diesel engine: The machine fails!

In "Image 1" below, a light film of oil is already visible on the clutch. This clutch is about to fail!

Images 2 and 3 show the cause of this leak: the hardened sealing ring!

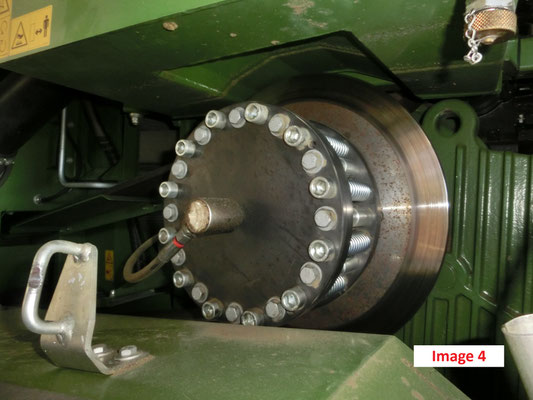

Up to approximately 700 hp, the old clutch can still withstand the temperatures encountered.

At higher power levels, converting to the new clutch shown in "Image 4" is advisable.